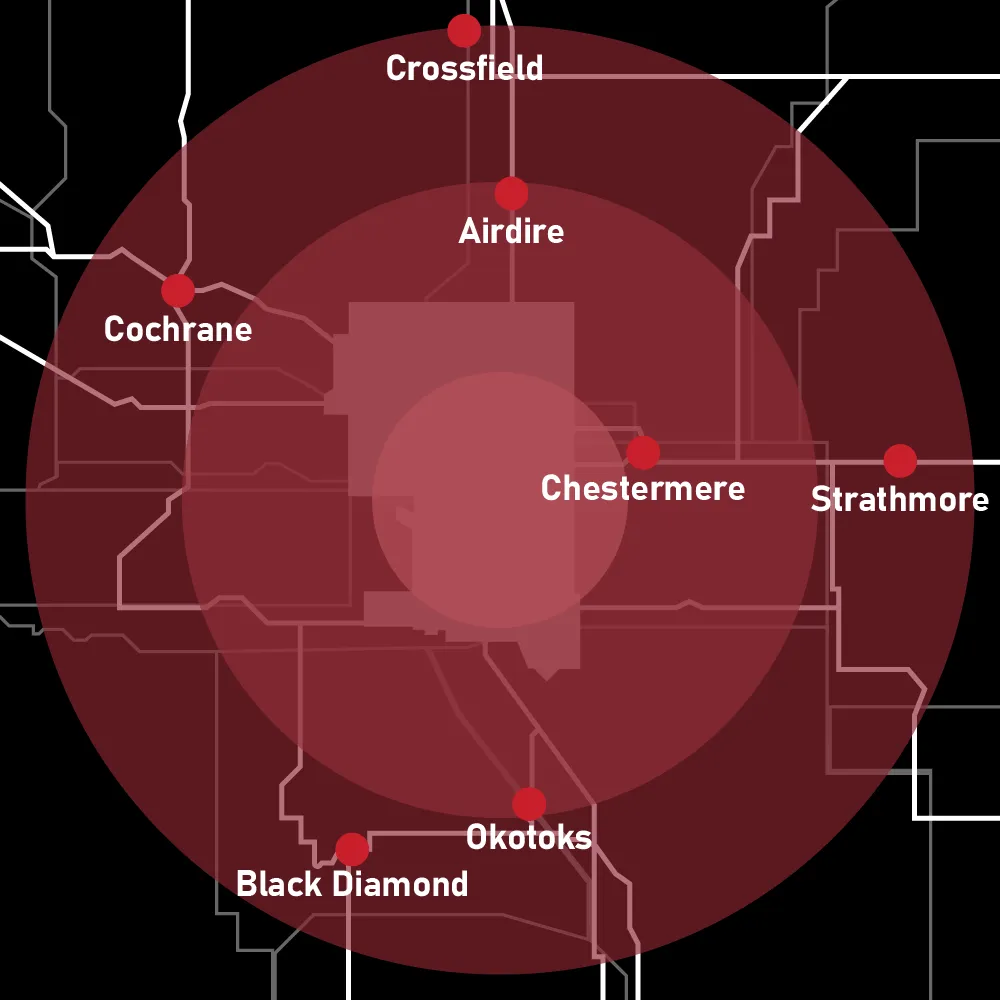

Operating heavy-duty trucks in Alberta places constant strain on critical systems due to extreme cold, rapid temperature swings, and aggressive winter road treatments. These conditions accelerate corrosion, degrade fluids, and increase mechanical stress across drivetrains, suspensions, and electrical systems. Rusted Nuts Mechanical Services supports owner operators and fleets across Alberta by addressing climate driven wear through targeted inspections and preventive maintenance tailored to regional operating conditions.

Why Alberta’s Climate Accelerates Truck Wear

Alberta experiences long winters, deep cold snaps, and frequent freeze thaw cycles. Trucks are exposed to subzero starts, heated highway operation, and repeated moisture exposure within short timeframes. This constant expansion and contraction stresses metals, seals, and fasteners while allowing moisture to penetrate joints, brake components, and electrical connections.

Common climate related stressors include:

- Rapid temperature swings within a single operating day

- Prolonged exposure to moisture and road spray

- Increased mechanical load during cold starts

Over time, these conditions compound and turn minor wear into major mechanical issues if not managed proactively.

Extreme Cold and Mechanical Stress

Cold temperatures increase resistance throughout mechanical systems. Metals contract, tolerances tighten, and rubber components stiffen. Engines experience higher load during cold starts, placing added stress on batteries, starters, and charging systems.

Components most affected by extreme cold include:

- Belts, hoses, and seals losing elasticity

- Starters and batteries working harder at startup

- Suspension components becoming more brittle under load

These stresses increase the likelihood of failures if components are already worn or poorly maintained.

Freeze Thaw Cycles and Moisture Damage

Freeze thaw cycles allow moisture to enter seams, fittings, and protective coatings. As water freezes, it expands, forcing apart joints and accelerating surface breakdown. When temperatures rise, moisture spreads contaminants deeper into mechanical and structural components.

This cycle commonly impacts:

- Brake assemblies and air system components

- Wheel ends and hub seals

- Suspension mounting points and fasteners

Repeated exposure significantly shortens service intervals if moisture intrusion is not addressed.

Road Salt Corrosion and Structural Deterioration

Winter road maintenance relies heavily on salt and chemical deicers, which significantly accelerate corrosion. Road salt corrosion attacks frames, crossmembers, brake lines, fasteners, and body panels, particularly when trucks are not washed frequently during winter months.

Areas most vulnerable to corrosion include:

- Frame rails and crossmembers

- Brake lines and fittings

- Electrical connectors and grounds

As corrosion advances, structural integrity weakens and routine service becomes more difficult due to seized bolts and damaged mounting points.

Cold Weather Effects on Fluids and Lubrication

Low temperatures thicken fluids, reducing flow during startup and increasing friction until operating temperature is reached. Engine oil, transmission fluid, and differential lubricants must maintain proper viscosity under extreme cold to protect internal components.

Cold related fluid issues often include:

- Delayed oil circulation at startup

- Increased wear during warm-up periods

- Reduced lubrication under high load

Selecting lubricants suited to Alberta conditions helps reduce startup wear and protect engines and drivetrains during heavy operation cycles.

Tires, Suspension, and Brake System Wear

Winter driving places added stress on tires, suspension, and braking systems. Cold temperatures reduce tire flexibility while snow and ice increase rolling resistance. Winter tires improve traction but still require proper inflation and inspection to perform effectively.

Seasonal wear commonly affects:

- Suspension bushings and shock components

- Brake calipers, drums, and air systems

- Tires experiencing uneven wear from cold pressure changes

Frozen road surfaces and potholes further accelerate suspension fatigue.

Electrical and Starting System Challenges

Electrical systems are especially vulnerable in cold weather. Batteries lose capacity as temperatures drop, while corrosion at terminals and connectors increases resistance. Wiring harnesses exposed to moisture and road spray are more likely to suffer insulation damage and intermittent faults.

Preventive checks typically focus on:

- Battery health and load testing

- Starter and alternator performance

- Terminal corrosion and ground connections

Addressing these areas reduces the risk of no-start situations during winter operations.

Climate Specific Preventive Maintenance Strategies

Preventive maintenance designed for Alberta conditions focuses on early detection and protection rather than reactive repair. This includes corrosion control treatments such as undercoating, seasonal fluid checks, and inspections targeting high risk components.

Effective climate specific strategies often include:

- Seasonal fluid analysis and viscosity checks

- Corrosion protection for frames and brake lines

- Pre winter inspection of suspension and braking systems

- Electrical system testing before cold weather peaks

Structured programs like heavy-duty preventive maintenance services support reliability in harsh operating environments.

Why Preventive Maintenance Matters More in Alberta

Climate driven wear increases the cost of reactive repairs and unexpected downtime. Trucks that receive regular inspections, corrosion protection, and fluid monitoring experience fewer in-season failures and longer component service life.

For Alberta operators, preventive maintenance is a reliability strategy that protects uptime and long term operating costs.

Next Steps for Fleet and Owner Operators

If your trucks operate year round in Alberta, climate aware maintenance planning makes a measurable difference. Routine inspections, proper fluid selection, and corrosion protection help reduce wear caused by cold, moisture, and road chemicals.

Contact us to discuss preventive maintenance planning, seasonal service strategies, and how climate specific care can keep your trucks operating reliably throughout Alberta’s toughest conditions.