Axles are one of the most important components in a heavy-duty truck. They carry the weight of the load, keep the wheels aligned, and transfer power from the driveline to the road. When an axle fails, the result is costly downtime, unsafe driving conditions, and expensive repairs. For Alberta fleets and independent operators, understanding what causes axle failure helps prevent breakdowns and keeps trucks on the road longer.

Overloading and Weight Stress

One of the leading causes of axle failure is overloading. Exceeding freight weight regulations puts extreme strain on axle shafts, differentials, and wheel bearings. Industries such as construction, oilfield hauling, and logging often push trucks to their limits. Consistent overloading leads to cracked housings, bent shafts, and premature bearing wear. Following proper weight limits is critical to avoiding axle failure.

Poor Lubrication and Bearing Wear

Axles and differentials require constant lubrication to reduce friction. Without enough gear oil or grease, components grind against each other, causing metal shavings, overheating, and eventual failure. Worn wheel bearings are especially dangerous because they can seize, leading to catastrophic axle damage. Regular lubrication checks are one of the simplest ways to protect an axle system.

Misalignment and Mechanical Strain

Axles that are out of alignment create uneven load distribution. This extra strain wears down one side of the axle faster and puts added stress on the driveline. Misalignment can be caused by improper installation, damaged suspension components, or repeated overloading. Correct alignment and regular inspections help extend axle lifespan.

Road Conditions and Environmental Factors

Alberta’s roads present unique challenges for heavy-duty trucks. Freeze thaw cycles create potholes that cause sudden impacts, while gravel haul roads and logging routes create constant vibration. Construction zones and rural highways also increase exposure to rough terrain. These conditions accelerate axle wear and often cause hidden cracks or fractures that worsen over time.

Warning Signs of Axle Failure

Catching axle problems early can prevent roadside breakdowns. Common warning signs include:

- Vibrations or shaking in the wheels or driveline

- Clicking or clunking noises from the differential area

- Leaking grease or gear oil near the axle housing

- Uneven or unusual tire wear

If any of these issues appear, professional inspection is necessary right away.

Inspection and Preventive Maintenance

Routine inspections are the best way to prevent axle failure. Checking lubrication levels, inspecting bearings, and scheduling regular service helps fleets avoid costly repairs. Preventive maintenance programs give truck owners peace of mind while keeping equipment compliant with safety regulations. Fleet operators also benefit from fleet services, which include scheduled inspections and record tracking for multiple vehicles.

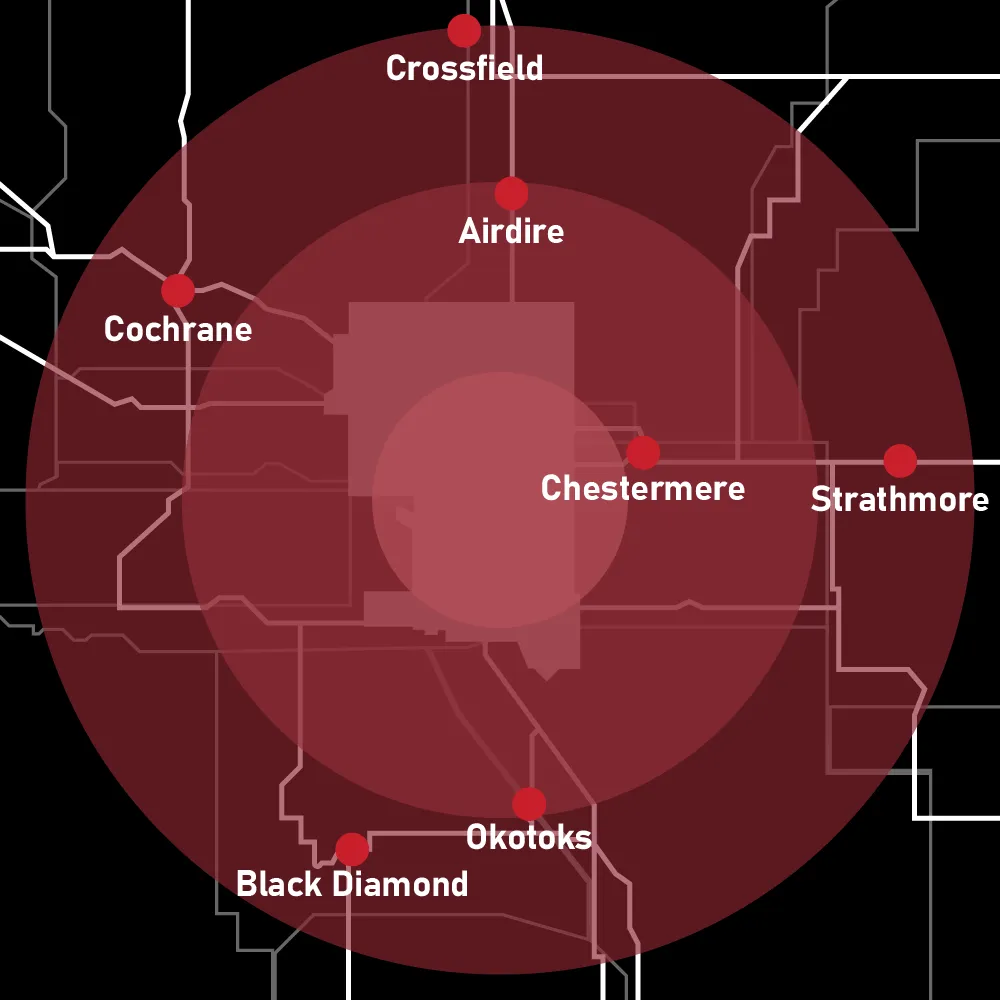

Professional Axle Repair in Calgary

Driving with a failing axle is unsafe and costly. Rusted Nuts Mechanical Services provides expert axle repair for heavy-duty trucks in Calgary and surrounding areas. From worn bearings to driveline misalignment, our technicians handle complex axle issues with precision. We also offer driveline repair, mobile truck repair, and roadside assistance to keep your truck moving when problems strike.

Protect your investment and reduce downtime by booking service today through our contact page.