Heavy trucks are the backbone of industries that rely on transporting goods across long distances. Keeping these vehicles in prime condition is not just about ensuring timely deliveries but also about maximizing the lifespan of the truck and minimizing operational costs. Understanding the most common heavy truck repairs can help owners stay ahead of potential issues, saving time and money while avoiding inconvenient breakdowns.

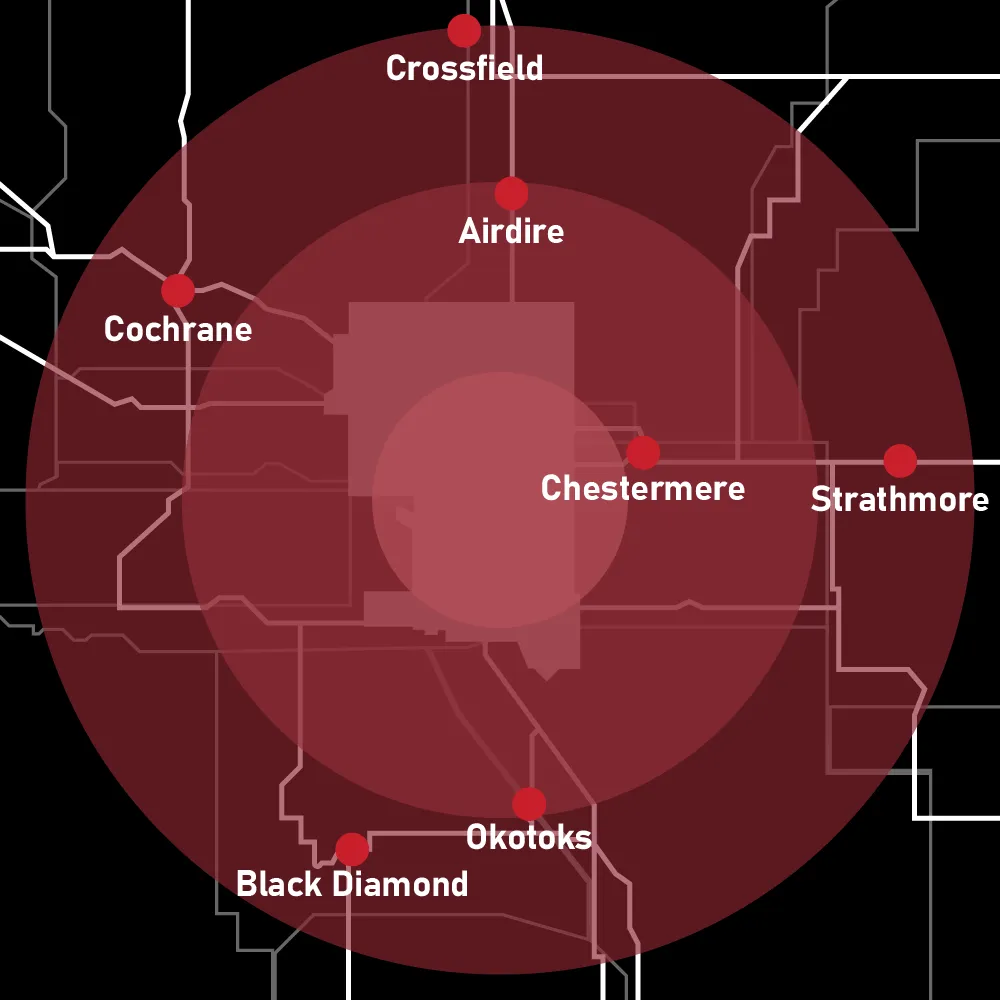

Regular maintenance is the cornerstone of a well-functioning fleet. At Rusted Nuts, we specialize in Fleet Maintenance Services, designed to address these common problems before they escalate. By staying informed and proactive, you can ensure your trucks are road-ready at all times.

1. Engine Problems

Common Issues

The engine is the heart of any heavy truck, and when it fails, the entire vehicle comes to a standstill. Common engine problems include overheating, oil leaks, turbocharger failure, and fuel injector issues.

Causes

- High mileage and wear-and-tear over time.

- Insufficient maintenance, such as missed oil changes or neglecting coolant levels.

- Clogged filters that reduce engine efficiency and lead to overheating.

Prevention Tips

- Schedule regular oil changes to keep the engine lubricated and running smoothly.

- Check coolant levels frequently to prevent overheating.

- Replace air and fuel filters during routine maintenance to ensure optimal performance.

Rusted Nuts offers comprehensive Engine Repairs and Diagnostics to tackle these issues head-on and keep your engine running efficiently.

2. Brake System Failures

Common Issues

Brake failures are one of the most critical safety concerns for heavy truck operators. Typical issues include worn brake pads, air leaks in the braking system, and damaged brake lines.

Causes

- Frequent stopping in urban or hilly terrains.

- Carrying heavy loads that strain the braking system.

- Lack of regular inspections to detect early signs of wear.

Prevention Tips

- Conduct brake inspections regularly to identify worn components early.

- Replace brake pads and repair leaks promptly to avoid system failure.

- Use high-quality brake fluid to maintain consistent performance.

For expert assistance, check out Rusted Nuts’ Brake System Repairs to ensure your truck’s braking system remains reliable.

3. Transmission Troubles

Common Issues

Transmission problems can result in gear slipping, grinding noises, or delayed shifting. These issues compromise the vehicle’s ability to operate effectively.

Causes

- Excessive towing or carrying heavy loads.

- Neglecting regular transmission fluid changes.

- Wear-and-tear on internal components over time.

Prevention Tips

- Schedule transmission fluid changes as recommended by the manufacturer.

- Address minor transmission issues promptly before they become major problems.

- Avoid overloading the truck beyond its capacity.

Rusted Nuts provides Transmission Repair Services to resolve these issues and keep your truck running smoothly.

4. Electrical System Malfunctions

Common Issues

Electrical problems are common in heavy trucks and often include dead batteries, faulty alternators, and wiring issues.

Causes

- Aging components and high mileage.

- Exposure to extreme weather conditions.

- Corrosion or damage to wiring over time.

Prevention Tips

- Inspect and clean battery terminals regularly.

- Test alternators during routine maintenance.

- Check and repair wiring to prevent short circuits.

Let Rusted Nuts handle your Electrical System Repairs to ensure all components are functioning properly.

5. Suspension System Issues

Common Issues

The suspension system ensures a smooth ride and proper handling. Problems like worn shocks, broken springs, and uneven tire wear can compromise vehicle performance.

Causes

- Driving on rough or unpaved roads.

- Overloading the truck beyond its weight capacity.

- Neglecting regular suspension inspections.

Prevention Tips

- Regularly inspect shocks, springs, and other suspension components.

- Rotate tires periodically to ensure even wear.

- Avoid overloading the truck to reduce strain on the suspension system.

Rusted Nuts specializes in Suspension Repairs to restore your truck’s handling and performance.

6. Cooling System Failures

Common Issues

Cooling system problems often manifest as radiator leaks, thermostat failures, or clogged hoses.

Causes

- Poor maintenance practices, such as neglecting coolant flushes.

- Exposure to extreme temperatures.

- Wear-and-tear on hoses and other components.

Prevention Tips

- Flush and replace coolant regularly to prevent overheating.

- Inspect hoses for signs of wear or damage.

- Address leaks promptly to avoid further complications.

For reliable solutions, turn to Rusted Nuts’ Cooling System Repairs to keep your truck’s temperature under control.

7. Tire and Wheel Problems

Common Issues

Tire and wheel problems, including blowouts, uneven tread wear, and wheel alignment issues, are frequent challenges for heavy trucks.

Causes

- Overloading the truck, leading to excessive tire wear.

- Improper tire inflation.

- Neglecting regular tire rotations and alignments.

Prevention Tips

- Monitor tire pressure regularly and inflate to recommended levels.

- Check tread depth and replace tires when necessary.

- Schedule routine alignments to prevent uneven wear and improve handling.

Rusted Nuts offers Tire and Alignment Services to address these issues and ensure safe driving conditions.

Conclusion

Heavy truck owners can save time, money, and avoid downtime by staying informed about the most common repairs. Proactive maintenance not only prevents costly repairs but also extends the lifespan of your vehicle, ensuring it remains a reliable asset for your business.

At Rusted Nuts, we’re committed to helping you keep your trucks road-ready with expert repair services and maintenance plans. Contact us today to schedule an inspection and take the first step towards worry-free operations.