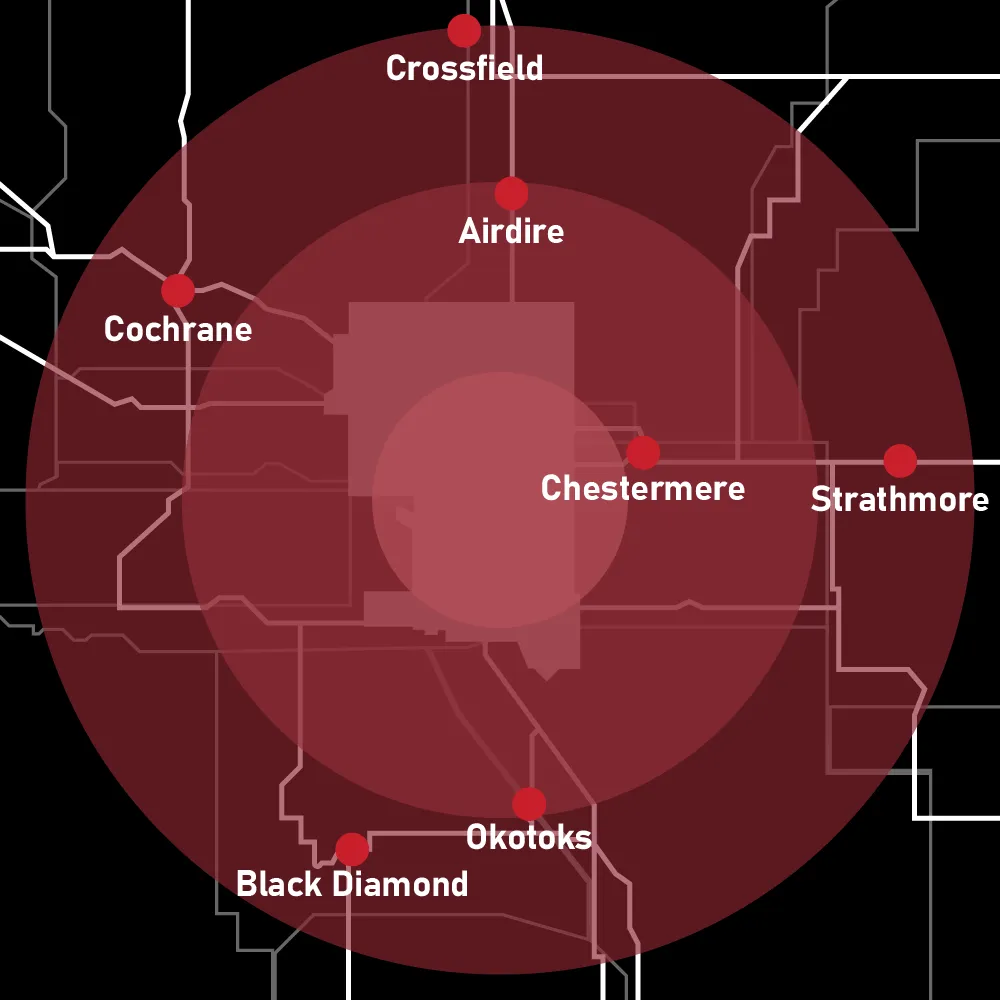

Heavy trucks operating in and around Calgary face a combination of urban traffic, highway hauling, weather extremes, and demanding workloads. These conditions contribute to recurring breakdown patterns that affect owner operators and fleets alike. Understanding the most common failure points helps reduce downtime, improve safety, and lower repair costs. Rusted Nuts Mechanical Services works with Calgary operators to identify these issues early and apply preventive strategies that keep trucks moving.

Why Heavy Truck Breakdowns Are Common in Calgary

Calgary’s operating environment creates unique challenges for heavy-duty trucks. Frequent stop and go traffic, elevation changes, and temperature swings place constant stress on braking systems, drivetrains, and electrical components. Winter conditions add road chemicals and cold starts, while summer hauling increases thermal load.

These factors accelerate wear when maintenance intervals are stretched or inspections are delayed.

Brake Failures and Air System Issues

Brake related failures are one of the most common causes of roadside breakdowns in the Calgary area. Air leaks, worn brake components, and frozen air lines often lead to reduced braking performance or system shutdowns.

Common brake related issues include:

- Air leaks from fittings, hoses, or valves

- Worn brake pads or shoes reaching service limits

- Moisture buildup in air tanks causing freezing

- Slack adjuster or chamber failures

Regular inspection and moisture management help prevent sudden brake related downtime.

Battery and Electrical System Breakdowns

Electrical issues frequently surface during temperature extremes. Cold weather reduces battery capacity, while corrosion increases resistance in wiring and connections. Inconsistent charging or weak batteries often result in no-start situations.

Typical electrical breakdown causes include:

- Failing batteries under cold load

- Corroded terminals and ground connections

- Starter or alternator wear

- Wiring damage from vibration or road debris

Routine testing and cleaning are key to preventing electrical failures during peak operating periods.

Tire Blowouts and Wheel End Failures

Tire failures remain a leading cause of roadside incidents. Improper inflation, uneven wear, and road hazards contribute to blowouts, especially under heavy loads.

Wheel end failures can follow when bearings, seals, or hubs overheat due to poor lubrication or contamination.

Common contributors include:

- Underinflated or overinflated tires

- Irregular wear patterns from alignment issues

- Heat buildup during extended highway operation

- Contaminated or degraded wheel end grease

Frequent inspections reduce the risk of sudden tire and wheel end failures.

Cooling System Leaks and Overheating

Cooling system problems often develop gradually but can lead to immediate breakdowns when leaks go unnoticed. Hoses, clamps, radiators, and water pumps are especially vulnerable under pressure and temperature changes.

Signs of cooling system issues include:

- Coolant loss or residue near fittings

- Temperature fluctuations under load

- Hose swelling or cracking

- Radiator or heater core leaks

Early detection prevents overheating that can cause severe engine damage.

Driveline and Suspension Failures

Driveline and suspension components absorb constant vibration, torque, and impact. Over time, joints, bushings, and mounts wear beyond tolerance.

Common failures include:

- U-joint wear leading to vibration or driveline separation

- Carrier bearing degradation

- Broken leaf springs or worn suspension bushings

- Shock absorber failure reducing vehicle control

Ignoring early symptoms often results in breakdowns that require towing rather than on-site repair.

Seasonal Breakdown Patterns in Calgary

Breakdown frequency often follows seasonal trends. Winter brings electrical, brake, and air system issues, while summer increases cooling system and tire related failures. Spring thaw introduces potholes that stress suspension and steering components.

Understanding these patterns allows operators to plan inspections and service before peak failure periods.

Preventing Breakdowns Through Inspections and Maintenance

Preventive maintenance is the most effective way to reduce breakdowns. Structured inspections identify wear before it leads to roadside failures. Regular servicing also supports compliance and safety requirements.

Key preventive measures include:

- Scheduled brake and air system inspections

- Battery and charging system testing

- Tire condition and pressure monitoring

- Cooling system pressure testing

- Driveline and suspension checks

Compliance focused inspections such as CVIP inspections also help identify safety issues before enforcement or breakdowns occur.

Roadside Response vs Planned Repair

When breakdowns occur, quick response minimizes downtime. Roadside repair is effective for many issues, but some failures require shop level repair or towing. Mobile fleet repair helps address problems early, reducing the likelihood of full roadside breakdowns.

Planning repairs in advance is always more cost effective than reacting to emergency failures.

Next Steps for Calgary Operators

If your trucks operate daily in Calgary, understanding common breakdown causes helps you stay ahead of failures. Regular inspections, seasonal maintenance, and early repairs reduce downtime and improve reliability.

Contact us to discuss preventive maintenance planning, roadside response options, and how proactive service can reduce breakdowns and keep your fleet operating efficiently in the Calgary area.