At Rusted Nuts Mechanical Services, we know how punishing Alberta’s winters can be on heavy-duty trucks. Coolant plays a vital role in keeping engines running reliably through freezing temperatures, yet it is one of the most overlooked maintenance areas. Following a proper coolant care routine helps prevent breakdowns, engine wear, and costly repairs during the coldest months of the year.

Why Coolant Maintenance Matters in Cold Climates

Coolant, also called antifreeze, keeps engine temperatures stable by transferring heat away from vital components. In cold weather, it prevents water inside the system from freezing and expanding, which could crack the block or damage hoses. It also contains additives that fight corrosion and lubricate the water pump.

Alberta’s harsh climate means engines face long idling periods and extreme temperature swings, both of which stress the cooling system. Without proper maintenance, coolant can degrade and lose its ability to protect the engine from freezing or overheating.

Check Antifreeze Concentration Regularly

The correct coolant mixture is essential for protection in sub-zero conditions. A mix that is too diluted freezes easily, while a mixture that is too strong can reduce heat transfer efficiency. The ideal ratio for Alberta winters is usually a 50/50 blend of antifreeze and distilled water, but some fleets run up to 60 percent antifreeze for added protection.

Use a coolant tester or refractometer to check the freezing point before winter. A well-balanced mixture ensures the system performs properly in temperatures that can dip below minus 40 degrees.

Choose the Right Coolant Type for Your Truck

Different engines require different coolant formulations. Most heavy-duty trucks use ethylene glycol-based coolants because of their strong antifreeze properties, but not all formulations are interchangeable. Mixing incompatible coolants can cause chemical reactions that lead to sludge buildup, corrosion, or scale inside the system.

Always use the type specified by the manufacturer, especially for engines equipped with modern emissions systems. Some newer trucks use extended-life coolants (ELC) designed for longer service intervals and improved protection under heavy loads.

Inspect Hoses, Radiator Caps, and Seals

Rubber components like hoses, gaskets, and radiator caps are vulnerable to wear and contraction in freezing weather. A cracked hose or loose cap can cause coolant loss, overheating, and air pockets in the system.

Inspect all connections for signs of leaks, swelling, or brittleness before temperatures drop. Replace weak components immediately, and make sure the radiator cap holds proper pressure to prevent coolant from boiling off during operation.

Schedule Routine Coolant Flushes

Even high-quality coolant breaks down over time. Contaminants, rust, and old additives reduce the fluid’s ability to protect against corrosion and freezing. Heavy-duty trucks that operate in extreme cold or harsh environments should have the cooling system flushed at least once every two years or per the manufacturer’s recommendation.

During a flush, technicians drain old coolant, clean the system, and refill it with a fresh, properly mixed solution. This process prevents buildup that could clog the radiator or water pump.

Use Block Heaters for Easier Winter Starts

Block heaters are an effective way to protect engines in freezing temperatures. By warming the coolant and engine block before startup, they reduce friction and allow oil to circulate faster. Plug in the block heater a few hours before starting the engine, or use a timer for consistent preheating.

A warmed engine not only starts easier but also reaches optimal operating temperature faster, reducing stress on internal components and improving fuel efficiency.

Common Mistakes to Avoid

A few simple errors can undo even the best maintenance efforts. Avoid topping off the system with plain water, as it lowers the freezing point and introduces minerals that cause scale buildup. Never mix different coolant brands or types without confirming compatibility. Ignoring low coolant warnings can lead to overheating or frozen lines that damage the radiator and pump.

Regular inspections and fluid testing go a long way toward preventing these costly issues.

Winter Coolant Maintenance Checklist

| Task | Frequency | What to Look For |

|---|---|---|

| Test antifreeze concentration | Before winter and mid-season | Freezing point near minus 40°C |

| Inspect hoses and radiator cap | Monthly | Cracks, leaks, or brittle rubber |

| Flush coolant system | Every 2 years or per OEM | Rust, sediment, or cloudy coolant |

| Check block heater operation | Weekly in winter | Plug condition, consistent warm start |

| Verify coolant level | Every refueling or inspection | Low reservoir or contamination signs |

This quick checklist helps fleet operators and truck owners track key maintenance tasks throughout Alberta’s cold season.

Trust Rusted Nuts Mechanical Services for Winter Maintenance

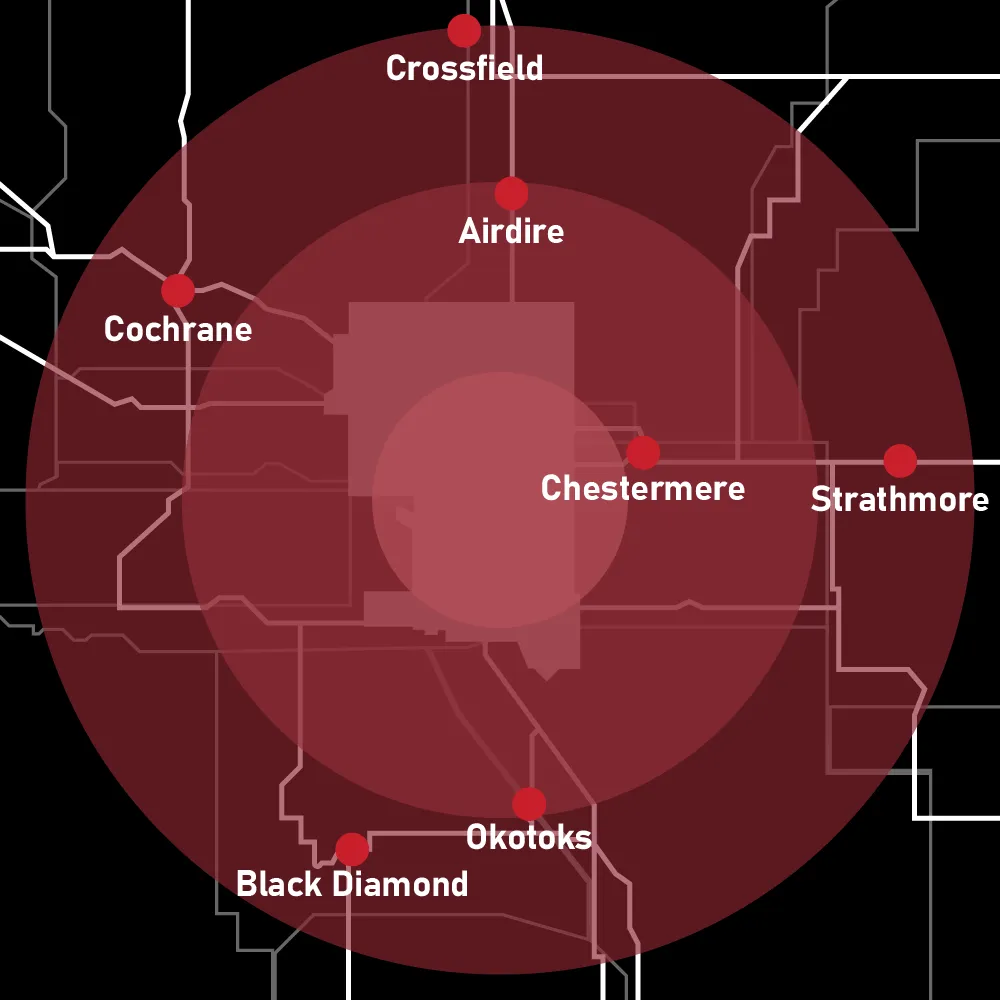

Proper coolant care is essential for keeping heavy-duty trucks running smoothly through Alberta’s toughest conditions. Rusted Nuts Mechanical Services provides complete winter maintenance services including coolant testing, system flushes, hose replacements, and block heater installations. Our team helps fleet operators and truck owners stay on the road safely through every season.

Learn more about our Fleet Services or Preventive Maintenance programs to protect your vehicles from winter wear.