A failing driveline can cause vibration, steering resistance, and knocking sounds that threaten both performance and safety. For commercial vehicles hauling heavy loads every day, catching driveline issues early prevents major repair costs and downtime. Rusted Nuts Mechanical Services provides professional heavy truck maintenance in Calgary, helping operators stay on the road safely and efficiently.

Common Warning Signs of Driveline Failure

The driveline is the mechanical link that transfers power from the transmission to the axles. It includes components such as the driveshaft, universal joints, carrier bearings, and slip yokes. When one part wears or loses balance, it throws off the entire system, leading to uneven torque delivery and vibration throughout the vehicle. These early symptoms often appear before total failure and serve as a critical warning for heavy truck owners and fleet managers.

- Vibration that increases with speed or load

- Clunking or metallic noises when shifting gears or taking off from a stop

- Resistance or jerking when turning

- Grease leaking from U-joints or carrier bearings

- Shuddering or wobbling under acceleration

Even a small imbalance in the driveshaft or worn U-joint can quickly lead to greater mechanical strain, damaging other components and reducing fuel efficiency.

What Causes Driveline Issues in Heavy Trucks

Several factors contribute to driveline damage, but most originate from wear, lubrication failure, or poor alignment. Each component must work together with exact tolerances to handle high torque loads safely.

- Worn universal joints (U-joints): Common from lack of lubrication or long service intervals

- Damaged carrier bearings: These support the driveshaft and can fail under heavy loads

- Bent or unbalanced driveshafts: Often caused by debris, potholes, or improper repairs

- Improper installation: Misalignment or incorrect torque settings lead to uneven stress

- Poor maintenance schedules: Missing preventive lubrication allows metal-on-metal wear

Routine inspections and lubrication significantly reduce these risks. You can learn more about preventive maintenance programs in Calgary designed to extend the lifespan of heavy-duty driveline parts.

Why Driveline Problems Should Never Be Ignored

Once vibration or noise becomes noticeable, damage is already occurring. The driveline operates under extreme stress, and continued driving with faulty components can create further failures in the transmission, differential, or suspension. Consequences of neglecting early signs include:

- Transmission or differential damage

- Increased wear on tires and suspension

- Safety risks from loss of control

- Costly roadside breakdowns and towing

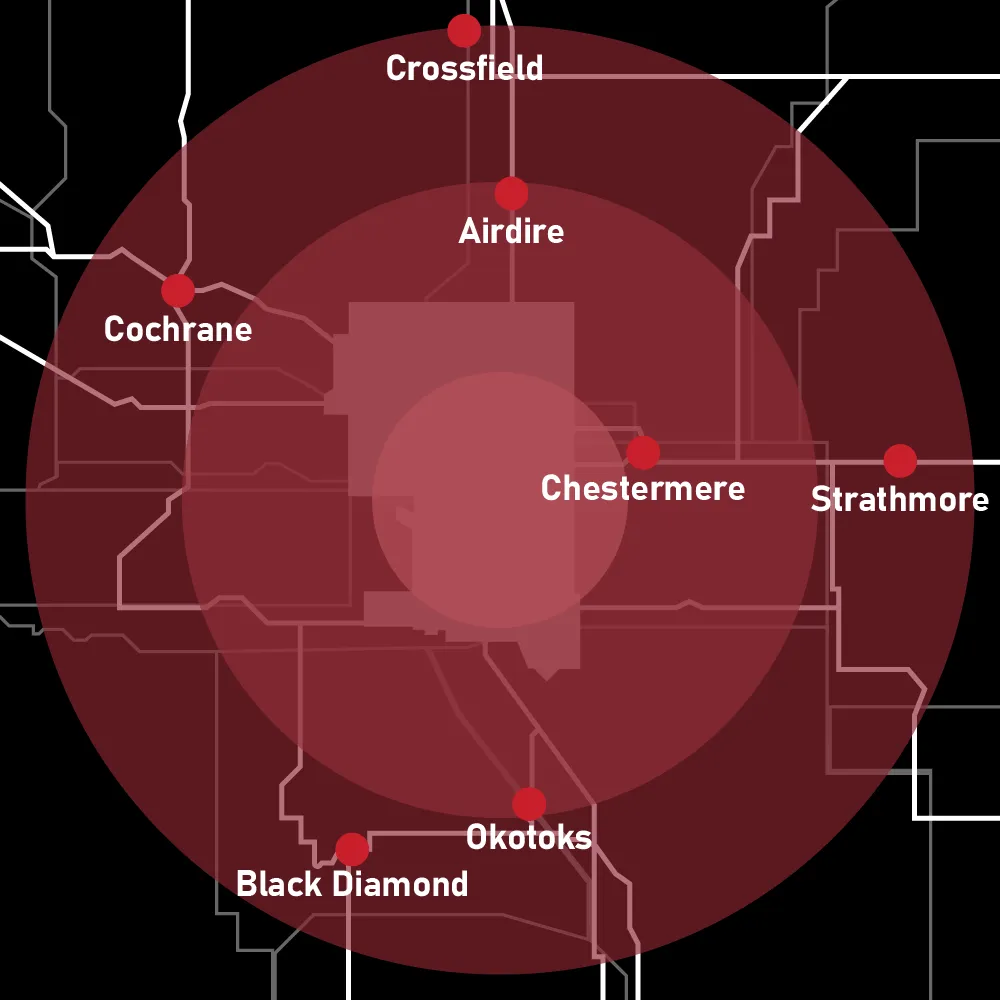

Addressing small problems immediately prevents downtime and preserves the truck’s performance. The driveline repair experts in Calgary at Rusted Nuts Mechanical Services specialize in diagnosing heavy-truck vibration issues and restoring full power transfer efficiency.

How to Prevent Future Driveline Damage

Heavy-duty trucks face demanding road and load conditions that wear parts faster than most vehicles. Preventive maintenance is the best defense. Schedule regular inspections to check for play in U-joints, inspect carrier bearings for looseness, and ensure the driveshaft remains balanced. Lubricate fittings on schedule and replace worn seals promptly.

Fleet operators can maintain consistent performance by working with Rusted Nuts Mechanical Services for reliable heavy-truck maintenance tailored to Alberta’s unique driving conditions.

Schedule Driveline Repairs in Calgary

Driveline problems worsen with every trip if left unchecked. If your truck shows signs of vibration, clunking, or steering resistance, get it inspected immediately. Rusted Nuts Mechanical Services provides complete repair and balancing solutions to keep fleets running safely. Book your service through the Rusted Nuts contact page to prevent costly breakdowns and extend driveline life.