When your vehicle breaks down, you might think all mechanics are the same—but that couldn’t be further from the truth. Heavy truck mechanics and auto mechanics serve two very different purposes in the automotive world. While they share some similarities, their training, tools, and the types of vehicles they work on make them vastly distinct.

Understanding the difference between these two professions is important for vehicle owners and businesses alike. Whether you own a passenger car or manage a fleet of heavy trucks, knowing who to turn to for maintenance and repairs can save you time, money, and frustration.

In this blog, we’ll explore what sets heavy truck mechanics apart from auto mechanics, diving into their scope of work, tools, training, and the unique challenges they face.

Scope of Work

Heavy Truck Mechanics

Heavy truck mechanics specialize in servicing and repairing large commercial vehicles like semi-trucks, buses, and trailers. These vehicles are built to handle heavy loads and endure long-haul trips, requiring mechanics to focus on durability and performance. Typical tasks for heavy truck mechanics include:

- Conducting full engine overhauls, often for diesel engines.

- Repairing and maintaining air brake systems, which are unique to heavy trucks.

- Diagnosing issues in hydraulic systems used for lifting or load-bearing components.

Unlike auto mechanics, heavy truck mechanics often deal with vehicles operating under extreme conditions, from cross-country freight to construction sites.

Auto Mechanics

Auto mechanics, on the other hand, focus on passenger vehicles, light trucks, and SUVs designed for everyday driving. Their work centers on keeping these vehicles running smoothly and efficiently for daily commutes or family use. Common tasks include:

- Routine maintenance such as oil changes, tire rotations, and brake pad replacements.

- Diagnosing and repairing gasoline engines and small electric components.

- Ensuring fuel efficiency and smooth performance for regular driving conditions.

While both professions aim to keep vehicles on the road, the scope of work for heavy truck mechanics is far more specialized and demanding due to the size and complexity of the vehicles they service.

Types of Systems and Components Serviced

Heavy trucks and passenger vehicles serve entirely different purposes, so it’s no surprise that the systems and components they rely on are vastly different. These differences directly affect the skills, expertise, and day-to-day tasks of the mechanics who work on them.

Heavy Truck Mechanics

Heavy truck mechanics deal with systems built for endurance, strength, and reliability under extreme conditions. These include:

- Air Brake Systems: Unlike passenger vehicles that use hydraulic brakes, heavy trucks rely on air brakes. These systems use compressed air, making them more reliable for stopping under heavy loads, but they require specialized knowledge for maintenance and repair. A mechanic must be adept at diagnosing leaks, adjusting brake chambers, and maintaining compressor systems.

- Diesel Engines: Diesel engines are the heart of heavy trucks, designed for high torque and fuel efficiency over long distances. These engines are more complex than gasoline engines, with components like turbochargers, aftertreatment systems (e.g., DEF and DPF), and high-pressure fuel systems requiring in-depth expertise.

- Heavy-Duty Suspensions: Designed to carry thousands of pounds, heavy truck suspensions include features like leaf springs and air suspension systems. Mechanics must ensure these systems remain durable and functional, often performing repairs on shock absorbers, bushings, and axle components.

- Hydraulic Systems: Many heavy trucks use hydraulic systems for steering, lifting, and braking. Troubleshooting hydraulic leaks and maintaining pumps, reservoirs, and hoses is a critical part of the job.

Heavy truck mechanics also encounter unique challenges such as diagnosing issues in multi-axle drivetrains and repairing trailers with advanced refrigeration or cargo systems.

Auto Mechanics

Auto mechanics, in contrast, focus on systems designed for comfort, efficiency, and safety in everyday driving. Their expertise often revolves around the following:

- Hydraulic Brakes: Found in nearly all passenger vehicles, hydraulic brakes are simpler and easier to maintain than air brakes. Tasks include replacing brake pads, calipers, and rotors, as well as flushing brake fluid.

- Gasoline Engines: Lighter and more compact than diesel engines, gasoline engines are optimized for quick acceleration and low emissions. Mechanics work on spark plugs, timing belts, and fuel injection systems, as well as diagnosing electronic controls that regulate performance.

- Comfort-Oriented Suspensions: Unlike heavy truck suspensions, car suspensions are focused on smooth rides and cornering stability. Auto mechanics often repair coil springs, struts, and sway bars to ensure a comfortable driving experience.

- Electrical Systems: Modern cars are equipped with increasingly sophisticated electronics, from infotainment systems to advanced driver-assistance systems (ADAS). Mechanics need to be skilled in diagnosing and repairing wiring issues, sensors, and control modules.

While the systems in passenger vehicles are less specialized than those in heavy trucks, they often require attention to detail due to the tight spaces and integration of modern technologies.

Tools and Equipment Used

The tools and equipment mechanics use play a significant role in the type of work they perform. From the size of the vehicle to the complexity of the systems, every aspect dictates the tools required for the job.

Heavy Truck Mechanics

Servicing heavy trucks requires a wide range of heavy-duty tools and equipment capable of handling oversized components:

- Hydraulic Lifts and Cranes: Unlike passenger vehicles, heavy trucks can weigh up to 80,000 pounds fully loaded. Mechanics use industrial-grade lifts, jacks, and cranes to safely raise these massive vehicles for undercarriage inspections and repairs.

- High-Capacity Torque Wrenches: Bolts and fasteners on heavy trucks are significantly larger than those in cars, requiring torque wrenches capable of applying hundreds or even thousands of foot-pounds of force. Mechanics need to ensure these fasteners are tightened to exact specifications to prevent failures.

- Advanced Diagnostic Equipment: Heavy trucks are equipped with complex onboard systems for engine management, air brakes, and fleet tracking. Mechanics use diagnostic tools specifically designed for commercial vehicles, such as J1939 or J1708 scanners, to troubleshoot issues.

- Welding and Fabrication Tools: Many repairs on heavy trucks involve welding and fabricating custom parts to replace worn or damaged components. This is particularly common for frames, exhaust systems, and brackets.

In addition to these tools, the facilities for heavy truck mechanics are often expansive, with enough space to accommodate large vehicles, trailers, and even fleets.

Auto Mechanics

Auto mechanics, working on smaller vehicles, use a different set of tools optimized for precision and accessibility:

- Standard Garage Lifts and Jacks: Passenger vehicles weigh significantly less than heavy trucks, so mechanics use compact hydraulic lifts and floor jacks. These tools allow easy access to the undercarriage for oil changes, brake replacements, and exhaust repairs.

- Hand Tools for Precision: Smaller engines and components mean auto mechanics rely on a variety of hand tools such as ratchets, wrenches, and screwdrivers designed for intricate work in tight spaces.

- OBD-II Scanners: Modern passenger vehicles come equipped with an On-Board Diagnostics (OBD) port, allowing mechanics to connect OBD-II scanners to read trouble codes and diagnose electronic issues. These tools are essential for identifying problems in the engine, transmission, and safety systems.

- Battery and Electrical Testing Tools: With the rise of hybrid and electric vehicles, auto mechanics increasingly use tools like multimeters and battery testers to work on electrical systems.

While auto mechanics may not require the heavy-duty tools used by truck mechanics, they must be highly adaptable, as they often service a wide variety of makes and models, each with unique repair needs.

Education and Training

The training required to become a mechanic is another area where heavy truck mechanics and auto mechanics differ. While both paths involve foundational skills in mechanics, the level of specialization and certifications needed set them apart.

Heavy Truck Mechanics

Heavy truck mechanics often undergo rigorous training focused on commercial vehicle systems. Their education includes:

- Specialized Diesel Training: Many heavy truck mechanics attend vocational schools or community colleges that offer programs in diesel engine repair and commercial vehicle technology. These programs cover everything from air brakes to powertrain systems.

- Certifications: Heavy truck mechanics typically pursue certifications like the Automotive Service Excellence (ASE) Medium/Heavy Truck certification. Additional certifications for air brake systems, diesel engines, and electrical diagnostics are often required to stay competitive in the field.

- Hands-On Apprenticeships: Apprenticeships with trucking companies or repair facilities provide invaluable real-world experience. Mechanics learn how to troubleshoot and repair complex systems under the guidance of seasoned professionals.

Because the work involves high-stakes repairs on vehicles critical for logistics and transportation, the training for heavy truck mechanics is both intensive and ongoing to keep up with new technologies and regulations.

Auto Mechanics

Auto mechanics typically focus on training geared toward smaller passenger vehicles and broader general skills. Their path includes:

- General Automotive Programs: Many auto mechanics complete programs at trade schools or technical colleges that cover gasoline engines, brake systems, and basic diagnostics.

- Certifications: ASE certifications are also valuable for auto mechanics, particularly those focusing on light vehicle systems like brakes, suspension, or electrical systems.

- Dealer-Specific Training: Mechanics working at dealerships often receive brand-specific training to specialize in particular makes and models, such as Toyota or Ford vehicles.

While auto mechanics’ training is comprehensive, it doesn’t involve the same level of specialization required for heavy trucks, as passenger vehicles generally have more standardized systems.

Work Environments and Job Challenges

The environments where heavy truck mechanics and auto mechanics work—and the challenges they face—are shaped by the type of vehicles they service.

Heavy Truck Mechanics

Heavy truck mechanics often work in larger facilities or on-site at trucking depots. Their work environment includes:

- Expansive Repair Bays: Heavy trucks require significant space for inspections, repairs, and parts storage. Facilities are often designed to handle multiple large vehicles at once.

- Mobile Repairs: Many heavy truck mechanics provide mobile repair services, traveling to breakdown sites or fleet yards. This adds an extra layer of complexity, as they must bring all necessary tools and troubleshoot in less-than-ideal conditions.

- Unique Challenges: Heavy truck mechanics deal with challenges like tight repair timelines for vehicles critical to supply chains. Repairs must be efficient to minimize downtime for businesses.

Auto Mechanics

Auto mechanics usually work in smaller garages or dealerships. Their environments are designed for convenience and efficiency:

- Compact Workspaces: Auto repair shops are smaller, as passenger vehicles don’t require as much room. Tools and lifts are scaled down to match.

- Controlled Environments: Most work is performed indoors, which minimizes environmental challenges like weather or lack of proper lighting.

- Diverse Vehicles: Auto mechanics face the challenge of working on a wide variety of makes and models, each with unique parts and systems.

The stakes for auto mechanics often revolve around customer satisfaction and ensuring safety for everyday driving, while heavy truck mechanics operate under the pressure of keeping industries moving.

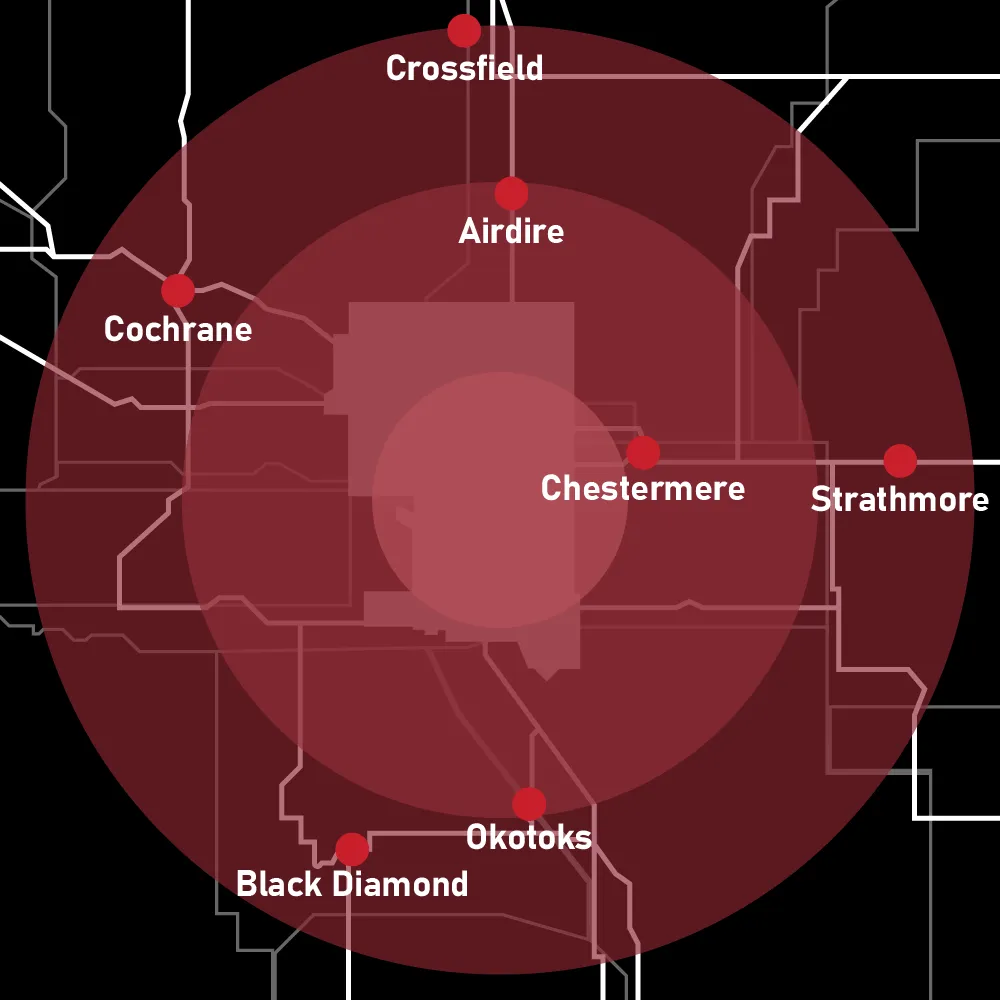

If your fleet of heavy trucks needs expert maintenance or emergency repairs, Rusted Nuts Mechanical is here to help. Our certified heavy truck mechanics specialize in diesel engines, air brake systems, and hydraulic repairs, ensuring your vehicles stay on the road and your business keeps moving. Whether you need routine maintenance or a last-minute fix, we’re equipped to handle it all.

Contact Rusted Nuts Mechanical today to schedule an appointment or inquire about our fleet services. Don’t let downtime slow you down—let us keep your trucks running at peak performance!