For heavy truck owners and fleet managers, maintenance is often seen as a necessary inconvenience—something you squeeze in between loads or when there’s finally a gap in your schedule. But skipping or delaying that maintenance can lead to massive repair bills, unexpected downtime, and a lot of lost revenue.

At Rusted Nuts Mechanical in Calgary, we’ve seen firsthand how small service delays turn into big problems. The good news? Most major repairs are avoidable. In this blog, we’ll break down how regular maintenance saves you thousands in truck repairs, what services to prioritize, and how a solid maintenance schedule pays off long-term.

The True Cost of Emergency Truck Repairs

When a truck breaks down unexpectedly, the bill doesn’t stop at just the parts and labour. The actual cost includes several hidden expenses:

- Towing and roadside assistance fees

- Missed deliveries and customer penalties

- Driver wait times and overnight accommodations

- Rental replacement vehicles

- Accelerated wear from neglected components

For example, a diesel engine overhaul can run well over $20,000 depending on the damage. Transmission failures often cost between $8,000 and $12,000. Even a neglected brake system can cost several thousand dollars if the rotors and air lines are damaged from prolonged wear.

Worse still, when one system fails, others are often affected. An overheating engine might crack a head gasket. Worn shocks may damage tires and suspension arms. Emergency repairs don’t just hit your wallet—they also throw your schedule into chaos.

What Regular Maintenance Includes

Regular truck maintenance doesn’t just mean changing the oil—it’s a full systems check designed to keep everything running smoothly. These basic services can extend your vehicle’s life and drastically cut repair costs over time.

Oil and Filter Changes

Oil is the lifeblood of your engine. It lubricates moving parts, reduces heat, and helps prevent wear. Dirty or degraded oil causes friction and buildup that can lead to severe engine damage.

By changing your oil and filters at recommended intervals—typically every 15,000 to 25,000 km for heavy-duty trucks—you reduce the chance of breakdowns and improve fuel efficiency. It’s a simple service that prevents costly repairs down the road.

Brake Inspections and Adjustments

Your truck’s brakes take a beating, especially on Alberta’s long descents and gravel roads. Regular inspections can catch worn pads, cracked drums, and leaking air lines early—before the entire braking system is compromised.

Replacing brake pads is a few hundred dollars. Replacing damaged rotors, calipers, or air brake components? That’s easily $2,000 to $5,000 or more, not including the cost of a missed load. Keeping up with brake service ensures your truck stops safely and saves thousands in potential repairs.

Tire Rotations and Pressure Checks

Tires are one of the most expensive consumables in a truck. Irregular wear, underinflation, or skipped rotations can reduce their lifespan by tens of thousands of kilometers.

Regularly rotating your tires and maintaining correct air pressure increases tire life, improves fuel economy, and reduces blowout risks. For fleets, extending the life of even one tire per truck saves thousands over time.

Electrical, Fluids, and HVAC Checks

Small electrical problems can spiral quickly. Corroded connectors, loose terminals, and weak batteries are easy to overlook—but they’re common causes of roadside breakdowns.

Coolant, DEF fluid, transmission fluid, and hydraulic fluid levels should be checked regularly. Overheating, poor shifting, or frozen lines can all stem from neglected fluids.

Even your truck’s HVAC system deserves attention—not just for driver comfort, but also because modern DEF systems often rely on temperature-regulated components. A failed HVAC system in -20°C weather could disable emissions systems and trigger a derate.

How Preventative Maintenance Saves You Money

Preventative truck maintenance means solving problems before they happen—or at least before they get worse. Here’s how it adds up:

- Lower repair bills: Small issues like leaks, loose belts, or worn bushings are inexpensive to fix. Left alone, they often cause major failures that require extensive labour and part replacement.

- Increased fuel efficiency: Clean filters, proper tire inflation, and regular oil changes help your truck run more efficiently, reducing fuel costs by up to 10%.

- Reduced downtime: Scheduled maintenance can be planned around your delivery schedule. Breakdowns never wait for a good time.

- Extended component life: Engines, transmissions, and other major systems last significantly longer when serviced regularly.

- Fewer repeat repairs: Fixing something right the first time—and maintaining it—means fewer trips back to the shop.

- Maintains warranty coverage: Most OEM warranties require proof of regular maintenance. Skipping service intervals can void your coverage, leaving you on the hook for the full repair cost.

Fleet Maintenance Savings: Real-World Impact

For fleet operators, these savings multiply. Maintaining one truck properly saves thousands a year—but across 5, 10, or 20 vehicles, the savings become even more dramatic.

- Planned service prevents fleet-wide disruptions

- Drivers report fewer complaints and service calls

- Predictable budgeting replaces surprise expenses

- Resale value stays high with documented service records

- DOT or CVIP compliance is easier with up-to-date maintenance logs

Fleet maintenance is one of the most controllable costs in your business—if you plan for it.

How to Build a Maintenance Schedule That Works

A maintenance schedule doesn’t need to be complicated. What matters is that it’s consistent, trackable, and tailored to your truck’s workload. Here are some simple steps to build an effective plan:

- Use kilometers or engine hours to schedule service. Long-haul trucks may go 20,000 km a month, while city delivery trucks rack up hours more than mileage.

- Break services into intervals—daily checks, monthly inspections, quarterly service, and annual overhauls.

- Track everything. Whether you use an app, spreadsheet, or paper logs, service records help you stay compliant and make smarter repair decisions.

- Partner with a reliable shop. A trusted local shop like Rusted Nuts Mechanical knows your truck, keeps accurate service records, and can help schedule repairs based on your actual use.

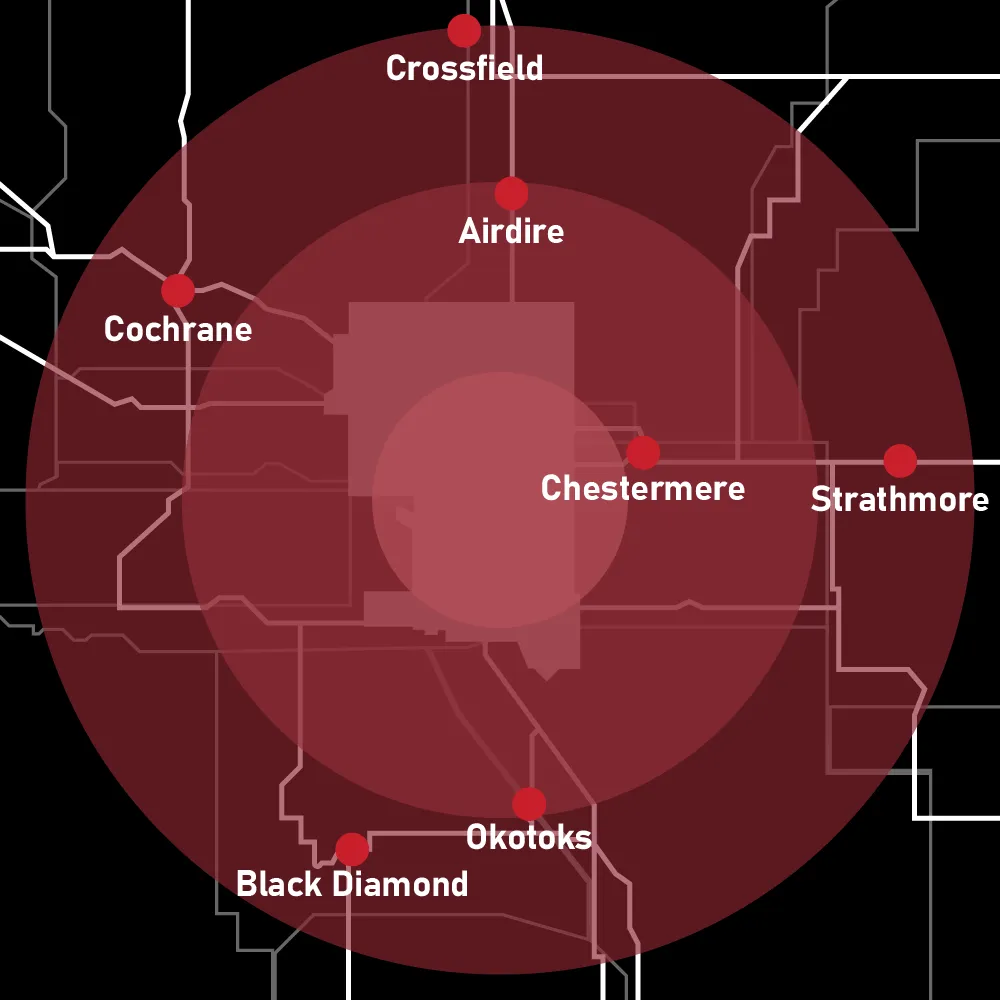

We help Calgary-based truck owners and fleet managers build maintenance plans that work with their operations, not against them. From one rig to an entire fleet, we’ll keep you running without surprise breakdowns or inflated bills.

Book Proactive Truck Maintenance in Calgary

If you’re tired of playing catch-up with repairs—or paying for expensive breakdowns that could have been avoided—it’s time to go proactive. At Rusted Nuts Mechanical, we offer full-service truck maintenance, CVIP inspections, and emergency repairs for heavy-duty trucks and trailers of all makes.

Whether you’re an owner-operator or managing a large fleet, our team can help you create a maintenance routine that fits your schedule and your budget. We make it easy to stay on track with service, and even easier to avoid the kind of costly failures that derail your operations.

Contact us today to book your next service or request a quote for fleet maintenance planning.

Conclusion

The most expensive truck repairs are often the most avoidable. Regular truck maintenance may not seem urgent, but it’s one of the smartest financial decisions you can make. By staying ahead of problems and sticking to a consistent service routine, you reduce major repair costs, limit downtime, and keep your trucks working hard instead of sitting in the shop.

At Rusted Nuts Mechanical in Calgary, we help truck owners save thousands every year with smart, preventative service. Let us help you protect your truck—and your business—with maintenance you can trust.